Industrial Robotic Automation System

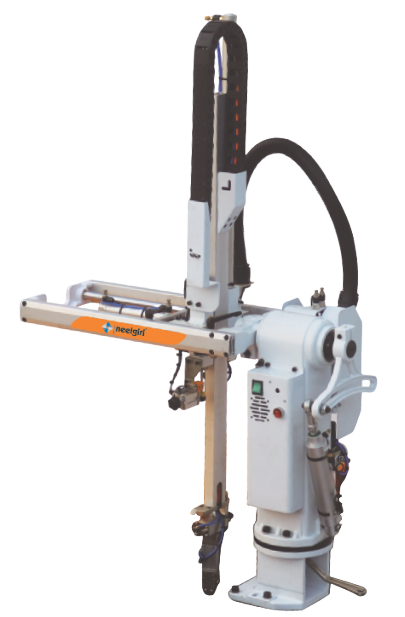

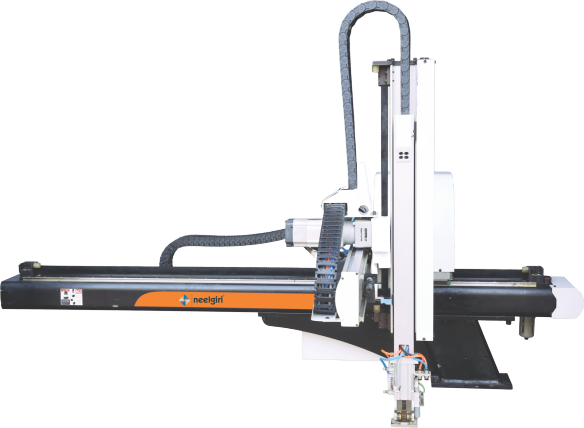

Servo Robots-Sprue Pickers

Servo sprue pickers are simple pick-and-place robotic devices used for spure removal or part and runner separation in plastic injection moulding automation. Servo sprue pickers range in size to fit 50 to 2400 ton plastic injection moulding machines. The X and Y axis, and A rotation, are all servo-driven for maximum flexibility and programmability

Pneumatic Swing Arm Robot

Pneumatic Sprue pickers are intended for automated sprue and part removal on plastic injection moulding machines up to 250 tons. After installation, the productivity will be increased, and also reduce defective rate, ensure safety of Operators, reduce manpower and accurately control the output to reduce waste.

Vertical Colour Mixer

Neelgiri Vertical Colour Mixers are suitable for granule – like material. It is mainly applied in plastic material mixing and also widely used in different industries. Itis an ideal mixing facility with five models, Handling capacity ranging from 50-300 kg.

Features

Both mixing barrel & mixer are made of stainless steel & polished, so has a very high brightness, easy to clean and absolutely no material contamination.

Mixing can be done in short period of time to save energy and has high performance.

Auto stop device can be set within 0-30 minutes.

Material discharging outlet has a manual shut-off plate for easy material clearance.

Both the body and its stand are fully welded to ensure solid structure.

Height adjustable on support frame, universal feet wheel & brakes make it very easy for adjusting & moving

SPECIFICATIONS

| Modal | Capacity (kg) | Power HP/KW |

Voltage V/Phase |

Revolving | Machine Size mm |

Weight kg (Approx) |

|---|---|---|---|---|---|---|

| NGV-50 | 50 | 2/1.5 | 380/3 | 46 | 650*1100 | 80 |

| NGV-100 | 100 | 3/2 | 380/3 | 63 | 850*1300 | 150 |

| NGV-150 | 150 | 4/3 | 380/3 | 63 | 900*1400 | 200 |

| NGV-200 | 200 | 5/4 | 380/3 | 63 | 1000*1600 | 280 |

| NGV-300 | 300 | 7.5/5.5 | 380/3 | 63 | 1150*1800 | 400 |

Hopper Dryer

DUST COLLECTOR

Additional dust collector installed to avoid plastic particles splashing and provide a clean environment.

Features

Optimized design and nice figure

Hot wind extending device of high efficiency and distributing evenly, so that high drying efficiency is achieved.

Special bend design ensure hot wind coming in a smooth way. Convenient for routine maintenance.

The hopper and the internal parts are made of stainless steel.

As the hopper body is separable from the bottom part. It is quite convenient of Hopper clearing and change to next material drying easily.

Overheat protection device to prevent operator’s injury or mechanical breakdown

Main power source switch for safety purpose

Magnetic base and normal base with transparent window optional.

SPECIFICATIONS

| Model | Capacity (kg) | Heating (Kw) | Blower (w) | Power (V/Phase) | Weight (kg) | Diameter |

|---|---|---|---|---|---|---|

| NGH-15E | 15 | 1.8 | 50 | 380/3 | 22 | |

| NGH-25E | 25 | 2.7 | 90 | 380/3 | 39 | 350 |

| NGH-50E | 50 | 4.2 | 180 | 380/3 | 50 | 400 |

| NGH-75E | 75 | 4.8 | 200 | 380/3 | 60 | 468 |

| NGH-100E | 100 | 7.8 | 250 | 380/3 | 75 | 550 |

| NGH-150E | 150 | 8.8 | 300 | 380/3 | 100 | 630 |

| NGH-200E | 200 | 10 | 400 | 380/3 | 150 | 700 |

| NGH-300E | 300 | 15 | 400 | 380/3 | 160 | 760 |

| NGH-400E | 400 | 20 | 400 | 380/3 | 200 | 800 |

| NGH-600E | 600 | 32 | 960 | 380/3 | 300 | 990 |

| NGH-800E | 800 | 32 | 960 | 380/3 | 400 | 1090 |

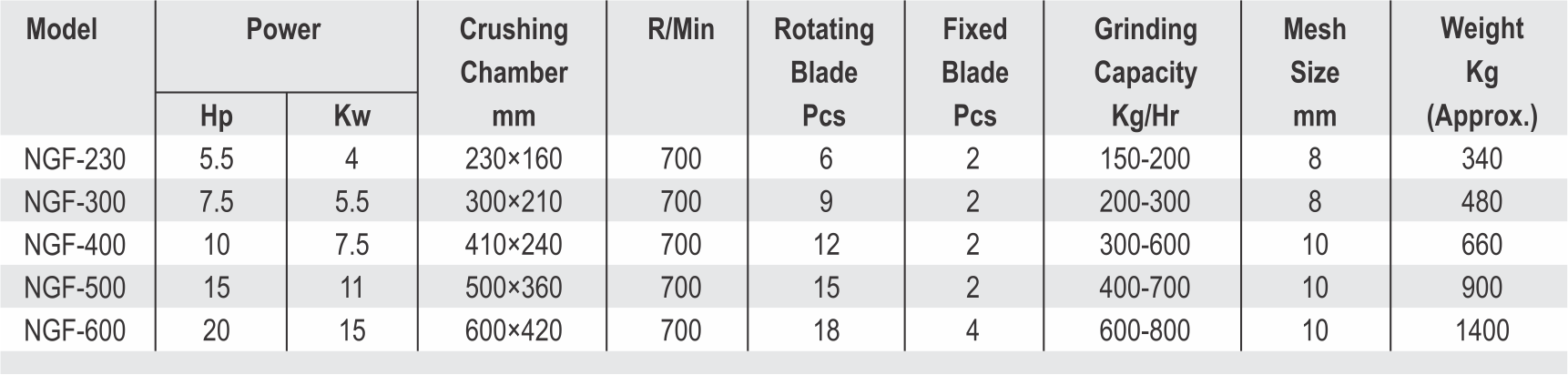

High Speed Granulator

Plastic recycling is simple when you choose a quality grinder by Neelgiri reduction solution.

Features

Integral body sturdy and durable, keep excellent performance after using long time.

Heavy-duty bearing & dust protection device the sound-proof boar can prevent vibration & noise effectively.

The overloading protector on the motor and interlock protection device on the power source, double protection for the safety of human being and motor.

Paddle-blades rotor adopting shear principle, made of high chromium steel.

The gap between blades is adjustable. The blades can be dismounted repeatedly for the purpose of re-sharpening.

Separable design, the bunker main body mesh frame are dismounted easily convenient for bunker cleaning.

With vibration-resistant feel reduce the noise of vibration.

SPECIFICATIONS

Hopper Loader

Neelgiri Vacuum Hepper Loader has a unique and effective vacuum suction, which is essential to upgrade modernisation features of the piastic industry.

Features

The main engine and the material hopper are designed separately, and thus it is safe, easy and convenient to be operated.

The whole operation is controlled by Micro Trip computer.

Equipped with an independent filter, which is very convenient to clean up dust.

The equipped muffler reduces the noise in operation.

Stainless steel material hopper is light in weight, durable and very convenient for cleaning the device

The control box, being designed separately, is easy to be well maintained

Auto-buzzer will give alarm while lacking material.

Auto-protetive device protects motor against over leading.

SPECIFICATIONS

| Model | Power

(Kw/Phase) |

Feeding Height Meter |

Static air-press Pcs |

Hopper

Ltr |

Tube Dia mm |

Weight kg (Approx.) |

|---|---|---|---|---|---|---|

| NGL-300G | 0.5/1 | 4 | 250 | 7.5 | 38 | 35 |

| NGL-400G | 0.75/3 | 4 | 300 | 7.5 | 38 | 43 |

| NGL-600G | 1.3/3 | 4 | 350 | 7.5 | 38 | 50 |

| NGL-800G | 1.5/3 | 4 | 400 | 7.5 | 38 | 54 |

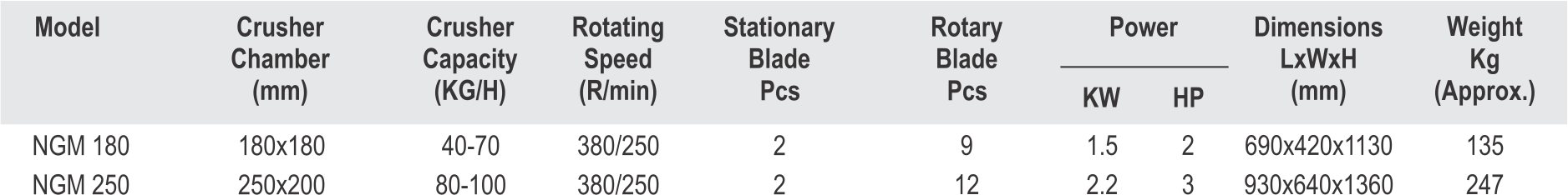

Medium Speed Granulator – Online

Features

Medium speed granulator online is suitable for recycling sprues from injection moulding machine and extrusion machine. It‘s easy to operate. It helps to reduce the nosie and possibilities of cutter the wearing. It also adopts required safety protection devices.

Small Size to save space.

Optimized design of blade saddle

No tool required for maintenance and cleaning up

Less dust, less noise and less energy consumption

High-grade safety

SPECIFICATIONS

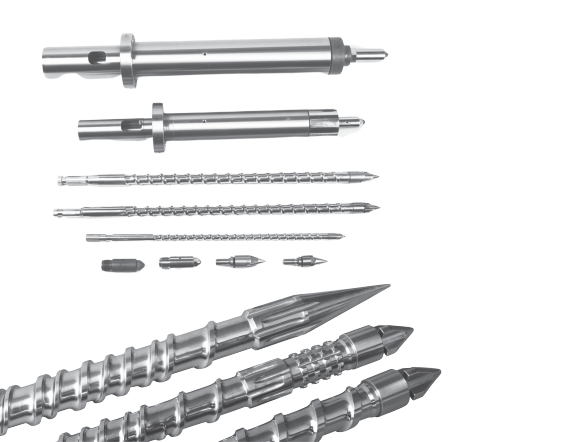

Screw Barrel

SCREW BARREL SPECIFICATION

1. The screw barrel size we make

Screw diameter: e15mm-e250mm

Screw length: 300mm-8000mm

Berral out diameter: e40mm-e400mm

2. The screw barrel technical indexes

Screw surface roughness: Ra0.4

Screw straightness: 0.015mm

3. Nitride screw barrel:

Material: 38CrMoA1-A

Nitride layer depth: 0.7mm

Nitride layer hardness: HRC63-68

4. Bimetallic screw barrel :

C-Class Bimetallic material: NPT1 (Fe, Co, Ni, W, Cr, A1)

Bimetallic layer: 2mm

Bimetallic layer hardness: HRC58-63

B-Class Bimetallic material: NPT2 (Fe, Co, Ni. W, Cr, A1)

All hard material import from Sweden

Bimetallic layer hardness: HRC60

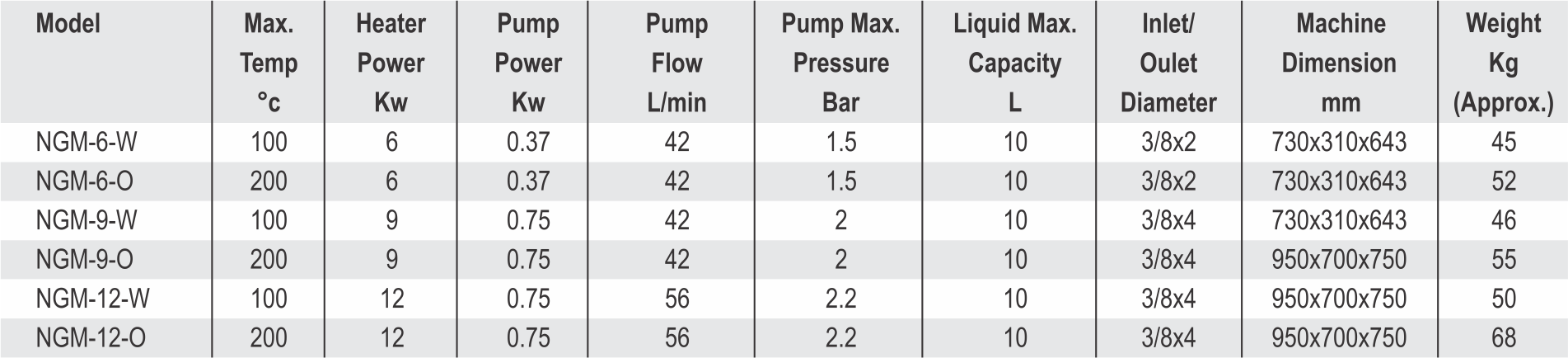

Automatic MTC

The Automatic mould temperature controller works on heat exchanging principle using water or oil to precisely control the mould temperature, this reduces the production time and thus produces quality products.

Features

Hot Medium Liquid: Water or oil convertibly; Either water or oil can be used as a hot medium liquid according to the needs of mould forming temperature. Its high selectivity is certain to bring in high economic efficiency.

Vertical Pump: The flow of vertical pump can be always kept steady and its service life keeps long.

Stainless Medium Tank: This interior tank will not get rust for long term, which is sure to prevent from any blockade 0f Pipes and keep long-term Service of pump

Automatic Alarming Device.

High-precision automatic temperature control.

Minimize product wastage

SPECIFICATIONS

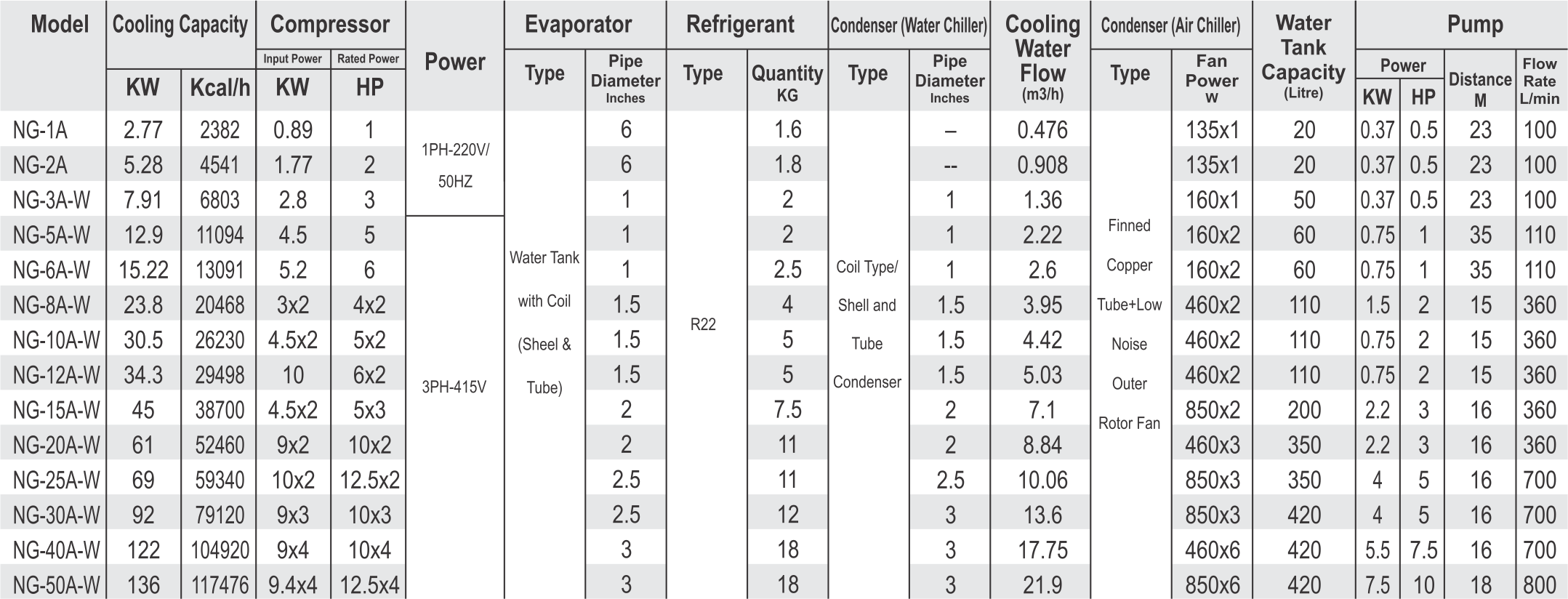

Industrial Chiller

Features

The water chiller is to provide a cooling process in plastic moulding, to improve quality of moulded products and shorten period of injection moulding cycles. Hence maximizes productivity of plastic moulding manufacturing.

Famous brand new compressors, high efficient shell condensers and evaporators—excellent cooling, quiet with low electric consumption.

P.I.D, Microprocessor control-easy to operate, accurately maintains temperature range from 30C to 500C

Special open type reservoir tank with stainless steel-easy to clean and maintain

Well designed and reasonable pipelines ensures power supply and saves energy.

Current-overload protector, high-and-low pressure switches, electronic time delayer, fault display system-safe and durable.

Liquid crystal display showing temperatures of outlet and Inlet chili water-provides visualized and direct setting.

Single, double or quadruple compressors combination available-economical and efficient.

Industrial designed-elegant and ergonomic

SPECIFICATIONS

Oven

A- Scope of Application :

- To de-moisturize plastic raw materials, especially in dealing with small amount of various materials or plastics for testing.

- Time saving during the refilling of the materials into the tray by faster material cleaning.

- Can be used in plastic moulding after tempering, which can enhance toughness, eliminate tension and improve quality of the plastic products

- Can also be used in agricultural products (pollen, garlic, tea) or preheat or dried for electronic, electrical, electroplating, pharmaceutical, paint, printing and other product.

B- Structural characteristics :

- Unique design of powerful air blow and air duct system, making sure the internal temperature distribution quality is trust worthy.

- With stainless steel shelves and circulating hot air recycling design-energy saving, durable suitable to dry serval to dry several of plastic

SPECIFICATIONS

| Model | External Dimension mm |

lnner Dimension mm |

Motor kw |

Power kw |

Tray Qty/Pcs |

Tray Size mm |

Weight Kg | Tray Material Stainless Steel |

Temperature Range |

Temperature Distribution |

|---|---|---|---|---|---|---|---|---|---|---|

| NGO 005 | 820*680*1280 | 500*600*660 | 4.5 | 5 | 585*490*50 | 148 | 50 | SUS4300# | 400 C-200 C | +/-5% |

| NGO 005 | 820*680*1580 | 500*600*900 | 6 | 9 | 585*490*50 | 178 | 90 | SUS4300# | 400 C-200 C | +/-5% |

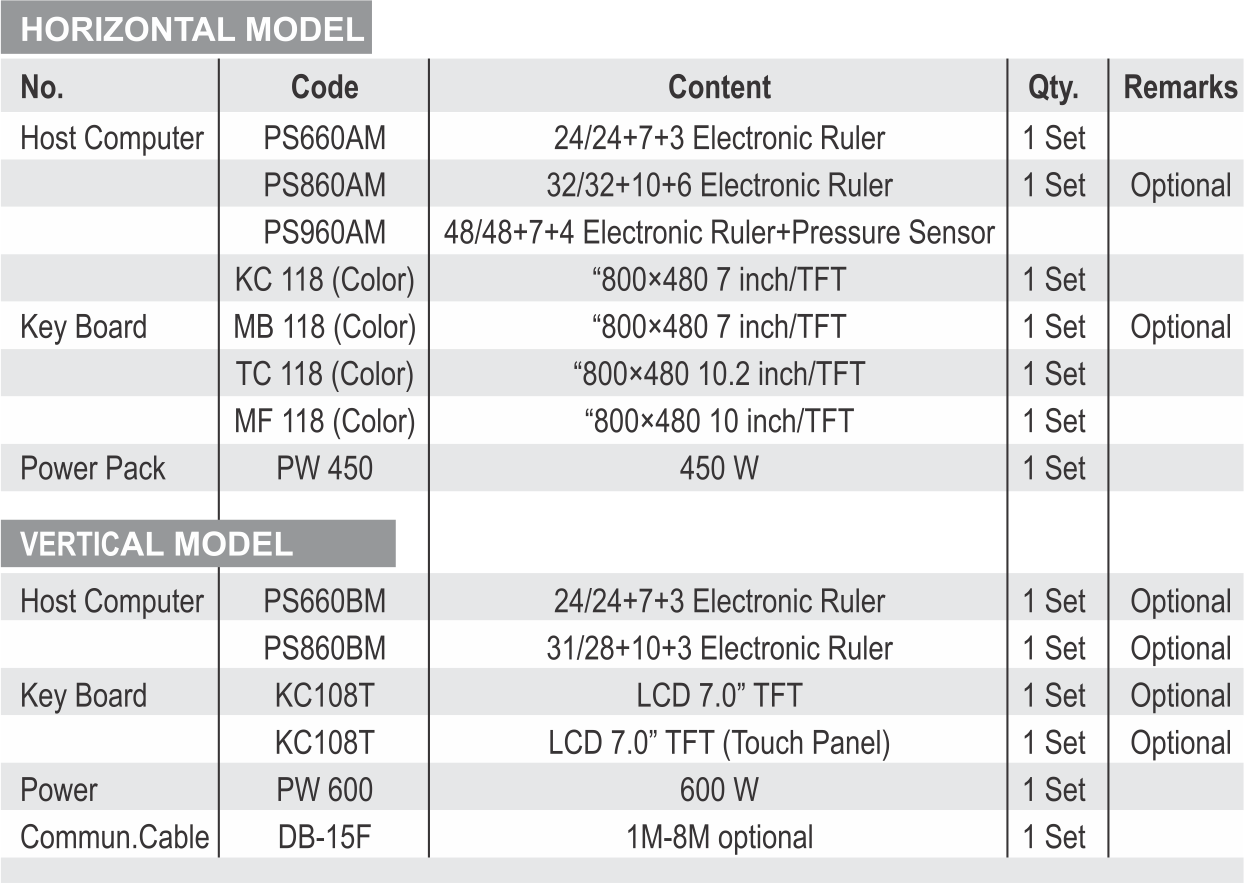

Injection Moulding PLC Controller

Characteristics of PS860AM Control System

The system has bright LCD display

The system adopts two CPU design with fast operating speed, precise control & high stability.

It has the real-time function to display time and date in real time.

With 999 groups of mode data storage, it may enter the mode description and real-time operating help in Chinese and English.

The password setting and data looking can prevent the operators from changing the established data arbitrarily to influence the quality of products.

There are multiple languages for your choice that display dynamically in real time.

Packing modulus setting funtion for 8-digit output may set the packing modulus

Various self-plugging and tein type programs are applicable for the self-plugging and tein control in different types

PID with self temperature control has (6+1) sections of temperatures.

Temperature may be preset a week in advance to enable more convenient operation

Failure Self-detection functions, alarm display & voice prompt Input and output are done by the optically coupled circuit to isolate the interference of the external circuitry.

In the inspection window, you can inspect all input and output points and the moving states of key.

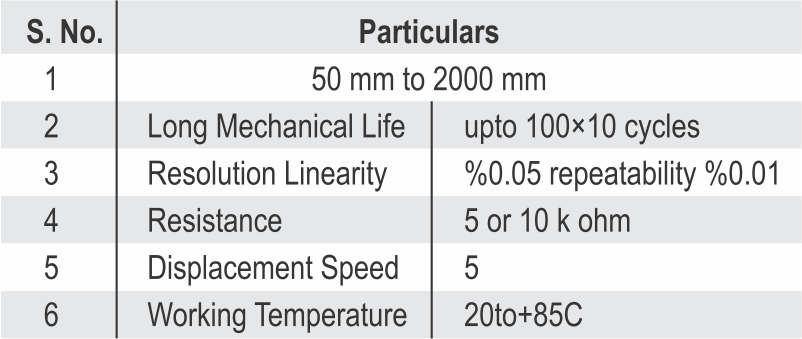

Linear Displacement Sensor

Features:

- True output linearity over the entire measurement range

- A fully active strain-gauge bridge to sense displacement giving infinite resoution and excellent linearity