NX Series Features

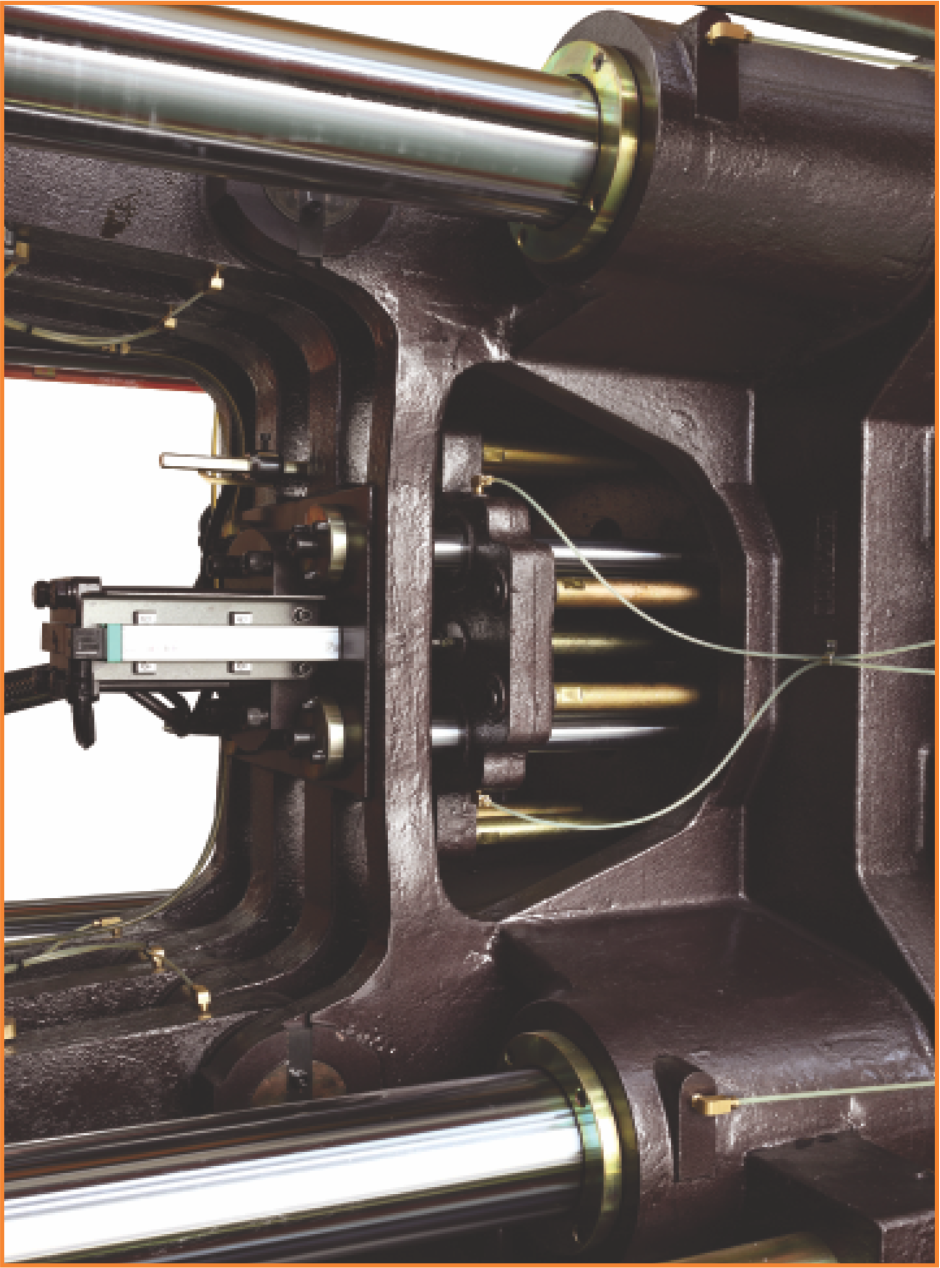

Robust and Reliable 5 point twin-toggle mechanism

Rugged clamp mechanism

Low platen deflection and better mould life

Highly energy efficient advanced Servo/VDP system

Better injection performance

Sub-flighted Screw for better melt homogeneity

Advance control system

Statistical process contol

Highly effcient plate type oil cooler

Quick reponse

Lower dry cycle time

Low noise and vibration

Larger daylight and longer opening storke

Wide and rigid clamping platens to accommodate large size moulds

Unique mould height adjustment

Lesser oil requirement

Features & Options

Injection Unit

Double cylinder balance for injection structure insures the injection base moves in parallel

Four-stage setting for injection speed, pressure and screw speed

Three-stage setting for pressure holding/material charging speed, pressure, and position

Injection position monitoring function

Injection position scale control

Automatic material cleaning function

Three option mode for suck back

Anti skid aluminum patterned cover

The temperature of barrel is controlled by computer PID

Ceramic heating device of barrel

Cooling temperature control system for barrel outlet

The back pressure adjusting function of stored material

Micro adjusting device of nozzle aiming

Screw speed detection

Modular selection of injection units.

Screw speed input in %

Injection speed input in mm/s

Nozzle guard with electrical interlock for operator safety

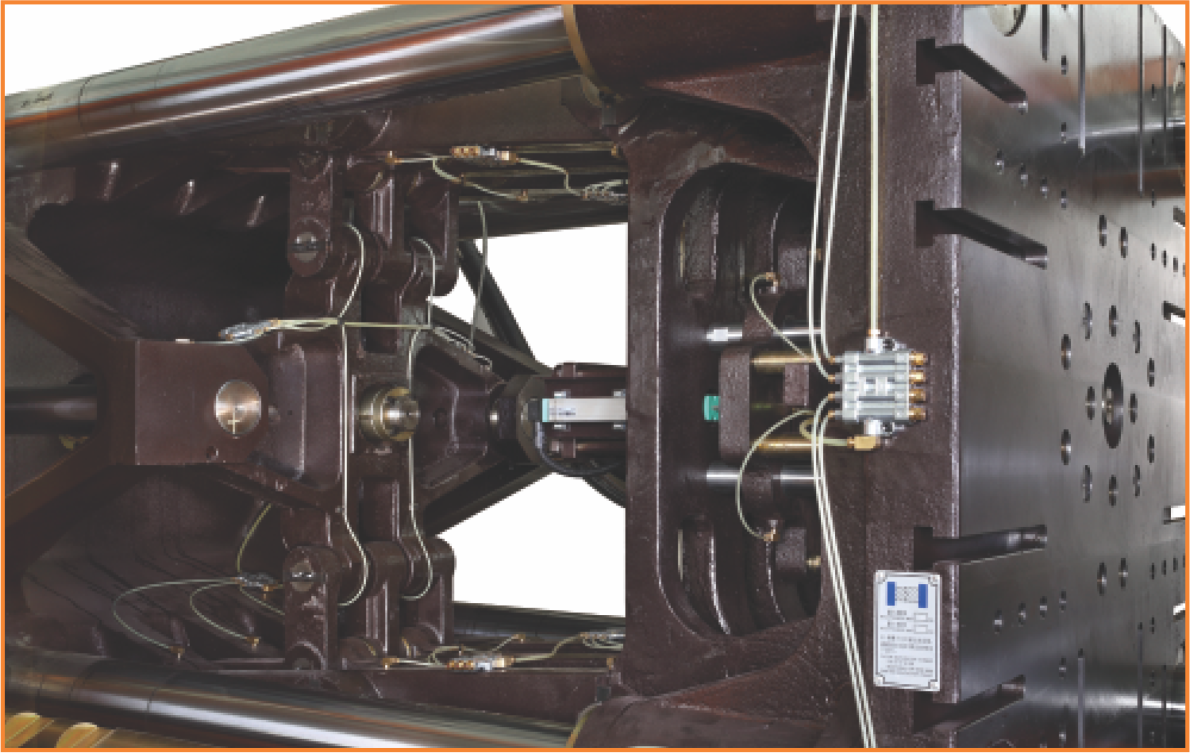

Clamping Unit

Digital four stage control for prreseure , speed, position of mould opening and closing.

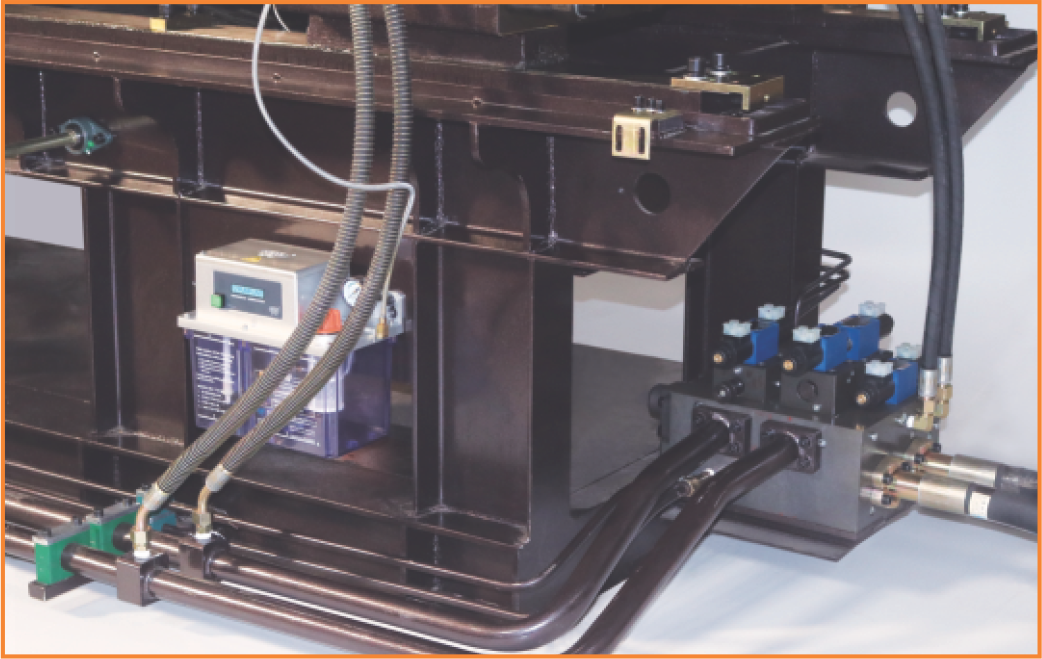

water manifold

Automatic centralized lubrication system

High speed mould clamping function.

Special treated tie bar with reliable strength.

Opening/closing mould, ijection position controlled by scale.

Automatic mould adjustment

Computer optimized 5-point twin toggle system, for fast, smooth platen movement and even distribution of clamp force

Toggle bushing grease lubricated automatically : lubrication signals computer optimised under adaptive control

Motorised mould height adjustment through sun & planetry gear mechanism

Low pressure mould safety

Low pressure and slow speed circuit for mould set up

Central hydraulic Ejector with multiple Stroke feature

Pressure and speed Independentally set in both directions

Ejector speed programmable in 2 stage

Central ejector rod

Hydraulic and electrical interlocks for safety gates

Mecganical drop bar for safety

Chrome plated tie bars

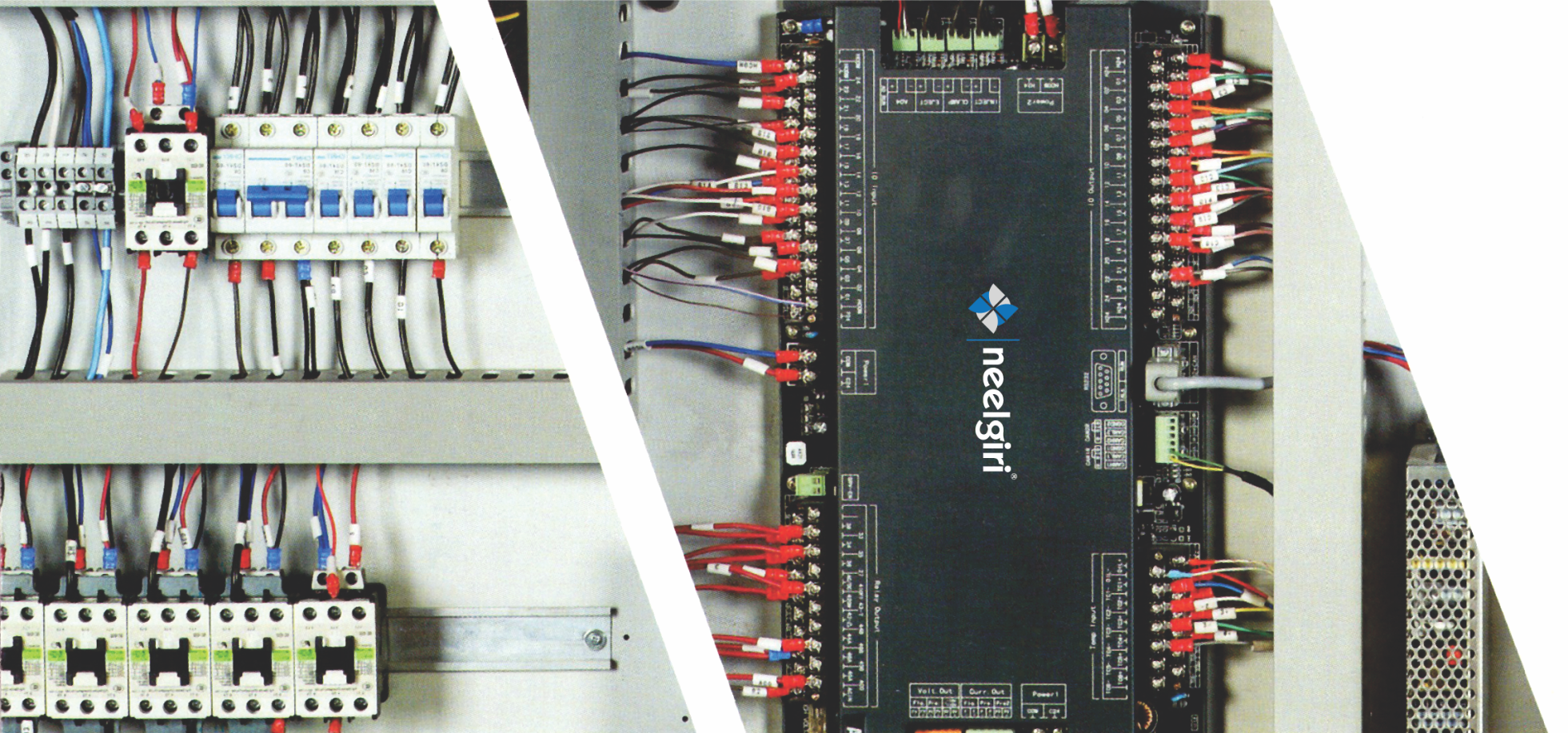

Electric Unit

Pre-setting of technical parameters

Electric interface of robot

Protection lock for parameter resource

10 inch Large-scale color LCD screen

The memory of mould in computer can reach 99 groups

Live detection to show running condition of each motion

Abnormal fuctional alarm system

Motor safe protection device

Systematic hardware I/O test fuction

3 Perparatory power pulgs for out supply power

Emergent stop protection function

Electric appliance and hardware inter-ware interlock protection function

Quality monitoring

Down time log

Set of electrical power outlets 3-ph 1*16A, 1Ph 1*10A

Process data statics-graphical display

Processing alarm

Diagnostic function-alarm help menu

LAN port for machine networking

Multi-level password function

Hydraulic Unit

Servo Pump system of high-Performance

Low noise hydraulic control system

Oil temperature deviation alarm system

Oil temperature pre-heating function

Tank oil level indicator

Oil filter core jam alam function

Hydraulic oil cooling device

Self-sealing oil filter of tank

Optional Setting

Special screw for special material

Mould temperature controller

Ejection during mould opening device

Multi-group core-pulling device

Insulation board of platen

Glass tube flow meter

Auto loader

Automatic safe door device

High precision by pass filter system

Proportional back pressure adjusting device

PQ closed-loop control

GSM connectivity for remote monitoring of machine status

Rebot interface as per JIS